andai semua kata kata dan cerita cerita dalam karyaku ini adalah kisah nyata dalam hidupku, mungkin aku tidak kan mampu membendung suka dan duka yang akan datang silih berganti,,,andai semua kata kata indah ini mampu kulukis setiap hari betapa menumpuknya kertas kertas gambar dan cat warna yang akan tertuang,,,akupun takkan mampu mendapat belaian belaian manis setiap hari dan akupun takkan mampu mendapat sakit hati dari perlakuan perlakuan kasih yang pahit jika itu ada,,,oh andai saja semua ini benar adanya aku hanya akan mampu berucap terimakasih buat semuanya karena papun ini aku harus menerimanya karena takdir dan nasib tidak bisa dirubah dalam sekejab,,,,wahai kasih yang bersembunyi dibalek layar lebar ini dimana dirimu,adakah engkau mendengarkan keluhan dan curahan hari ini????…wahai kasih yang belum sampai dimana gerangan dirimu yang bersembunyi dibalik awan dan hujan,akankan engkau menyapaku dan menghampiriku????dan adakah seorang belahan jiwa

yang akan menjadi kasihku?????,,,,khayal dan khayal takkan pernah berhenti sampai disini…..

Sunday, April 18, 2010

BLAST EFFICIENCY

MAJOR FACTORS INFLUENCING BLAST EFFICIENCY

1. ATTITUDE

a. PAYING ATTENTION TO DETAILS

b. EACH OPERATION MUST BE COMPLETED AS PRECISELY AS POSSIBLE

c. TOTAL QUALITY MANAGEMENT (T.Q.M)

d. GROUP EFFORT

2. COMMUNICATION

a. SAFE BLASTING PRACTICES REQUIRE GOOD COMMUNICATION.

b. COMMUNICATION BETWEEN MEMBERS OF SAME GROUP AND BETWEEN GROUPS.

c. OPTIMUM BLAST DESIGNS DEPEND ON INPUT FROM EACH GROUP.

3. BLAST DESIGN

KEYS TO EFFICIENT BLAST DESIGN

a. UNIFORM ENERGY DISTRIBUTION

b. APPROPRIATE ENERGY CONFINEMENT

c. PROPER ENERGY LEVEL

d. ADJUSMENT OF DESIGN TO MEET - EXISTING CONDITIONS

APPROACH TO ACHIEVING OPTIMUM BLAST EFFICIENCY

4. GEOLOGICAL EFFECTS

Blasting results are influenced more by rock properties than explosive properties.

Rock properties:

Compressive strength >> Tensile strength

a. Rock Structure:

a.1. Rock fragmentation is primarily controlled by bedding, jointing, and faulting.

a.2. Smaller drill pattern minimize the adverse effects of bedding and fractures but increase drill and blast costs.

a.3. Explosives with high gas production (ANFO) are appropriate for highly jointed or fractured rock.

a.4 The orientation of the free face to the joints sets is also a key consideration for fragmentation and wall control.

Water

a. Static water

b. Dynamic water

c. Multiple priming is advised in wet blast hole

1. ATTITUDE

a. PAYING ATTENTION TO DETAILS

b. EACH OPERATION MUST BE COMPLETED AS PRECISELY AS POSSIBLE

c. TOTAL QUALITY MANAGEMENT (T.Q.M)

d. GROUP EFFORT

2. COMMUNICATION

a. SAFE BLASTING PRACTICES REQUIRE GOOD COMMUNICATION.

b. COMMUNICATION BETWEEN MEMBERS OF SAME GROUP AND BETWEEN GROUPS.

c. OPTIMUM BLAST DESIGNS DEPEND ON INPUT FROM EACH GROUP.

3. BLAST DESIGN

KEYS TO EFFICIENT BLAST DESIGN

a. UNIFORM ENERGY DISTRIBUTION

b. APPROPRIATE ENERGY CONFINEMENT

c. PROPER ENERGY LEVEL

d. ADJUSMENT OF DESIGN TO MEET - EXISTING CONDITIONS

APPROACH TO ACHIEVING OPTIMUM BLAST EFFICIENCY

4. GEOLOGICAL EFFECTS

Blasting results are influenced more by rock properties than explosive properties.

Rock properties:

Compressive strength >> Tensile strength

a. Rock Structure:

a.1. Rock fragmentation is primarily controlled by bedding, jointing, and faulting.

a.2. Smaller drill pattern minimize the adverse effects of bedding and fractures but increase drill and blast costs.

a.3. Explosives with high gas production (ANFO) are appropriate for highly jointed or fractured rock.

a.4 The orientation of the free face to the joints sets is also a key consideration for fragmentation and wall control.

Water

a. Static water

b. Dynamic water

c. Multiple priming is advised in wet blast hole

Labels:

Blasting

Friday, April 9, 2010

Mining Accidents

05 November 2007 at 05.15 am high wall block 10 EX 062

11 November 2007 at 16.30 pm KM 73 Construction

Labels:

Accidents,

Mining,

Mining Accidents

Wednesday, April 7, 2010

MINING CONCEPTS

FACTOR:

1. Form and reserve position (flat-tilted-up)

2. Topographic contours and roof / floor coal (box set's first cut / first-cut box)

3. Stripping Ratio

PRINCIPLE:

1. Expose the direction of the high wall into the low wall (tilt-up)

2. Expose the direction of the low wall into the high wall (flat-sloping)

3. Mining the direction opposite to the direction of water

4. Make the first box-cut coal at the lowest elevation

Resources Oblique - Vertical

Resources Flat - Sloping

CONTOUR EFFECT ON COAL MINING CONCEPTS

SR EFFECT OF MINING ON THE CONCEPT

1. LOW STRIPPING RATIO

2. HIGH STRIPPING RATIO

TYPICAL MINING SEQUENCE

a. Drilling & Blasting

b. Overburden Removal

c. Coal Exposing

d. Coal Extraction

MINING SEQUENCE-ILLUSTRATION

STANDARD PARAMETERS

1. Production Process

Overburden Removal

Coal Getting

Coal Crushing and Barge Loading

2. Road Width

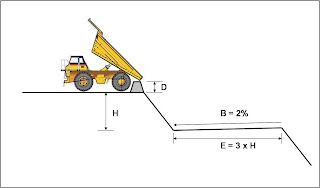

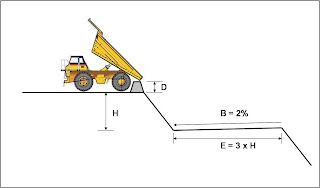

STANDARD PARAMETER OF OPERATION ROAD DESIGN

3. Front Width

Working Space Dimension

Bench Width = 3 x Turning Radius

Bench Height = Heights of Vesse

4. Fleet Matching

5. Pay load distribution

6. Disposal Management

Disposal Re-shaping

1. Form and reserve position (flat-tilted-up)

2. Topographic contours and roof / floor coal (box set's first cut / first-cut box)

3. Stripping Ratio

PRINCIPLE:

1. Expose the direction of the high wall into the low wall (tilt-up)

2. Expose the direction of the low wall into the high wall (flat-sloping)

3. Mining the direction opposite to the direction of water

4. Make the first box-cut coal at the lowest elevation

Resources Oblique - Vertical

Resources Flat - Sloping

CONTOUR EFFECT ON COAL MINING CONCEPTS

SR EFFECT OF MINING ON THE CONCEPT

1. LOW STRIPPING RATIO

2. HIGH STRIPPING RATIO

TYPICAL MINING SEQUENCE

a. Drilling & Blasting

b. Overburden Removal

c. Coal Exposing

d. Coal Extraction

MINING SEQUENCE-ILLUSTRATION

STANDARD PARAMETERS

1. Production Process

Overburden Removal

Coal Getting

Coal Crushing and Barge Loading

2. Road Width

STANDARD PARAMETER OF OPERATION ROAD DESIGN

3. Front Width

Working Space Dimension

Bench Width = 3 x Turning Radius

Bench Height = Heights of Vesse

4. Fleet Matching

5. Pay load distribution

6. Disposal Management

Disposal Re-shaping

Labels:

Mining

Basic Surface Mining

Surface Mining

1. Contour Mining

2. Strip Mining

3. Open Pit Mining

4. Open Cast Mining/ Mountain top Removal MTR)

5. Quarry Mining

OPEN CAST MINING/MOUNTAINTOP REMOVAL

The Types of Mining Methods

a. Truck and Shovel

b. Dragline

c. Direct Dozing

Integrated Dozer push and Truck Shovel (Dozer Method Flat Dip and 8o)

Example Dozer Method

Example Dozer Method Cross Section

Direct Dozing Method

Downhill – Dozer Wedge

4. High wall Mining (Auger Mining)

High Wall Mining Configuration

High Wall Mining Equipment

a. Auger Machine

b. Auger Drills

c. Auger Holes

d. LAUNCH VEHICLE

e. COAL EXTRACTION ACTIVITY

5. Continuous Mining

Continuous Mining Diagram

Continuous Mining

1. Contour Mining

2. Strip Mining

3. Open Pit Mining

4. Open Cast Mining/ Mountain top Removal MTR)

5. Quarry Mining

OPEN CAST MINING/MOUNTAINTOP REMOVAL

The Types of Mining Methods

a. Truck and Shovel

b. Dragline

c. Direct Dozing

Integrated Dozer push and Truck Shovel (Dozer Method Flat Dip and 8o)

Example Dozer Method

Example Dozer Method Cross Section

Direct Dozing Method

Downhill – Dozer Wedge

4. High wall Mining (Auger Mining)

High Wall Mining Configuration

High Wall Mining Equipment

a. Auger Machine

b. Auger Drills

c. Auger Holes

d. LAUNCH VEHICLE

e. COAL EXTRACTION ACTIVITY

5. Continuous Mining

Continuous Mining Diagram

Continuous Mining

Labels:

Mining

Subscribe to:

Comments (Atom)