Loading Point

Haul Road

Dumping Area

Haul Road

Haul Road Definition :

EFFICIENT HAUL ROAD

The following criteria needs to be taken into consideration in haul road design :

- Road Width

- Material Structure

- Rolling Resistance

- Grade Resistance

- Crossfall

- Superelevation

- Drainage

- Safety Berm

Road Width

Material Structure

a. A well structured and drained haul road is critical to the efficient operation of haul trucks.

b. The road base geometry is dependent on the capacity of the truck and the materials available.

c. Not all mines have the same base material properties….. But as long as the CBR (Californian Bearing Ratio) value is know, the depth of the base can easily be determined for a particular load.

d. The attached table, demonstrates a typical pavement cross section for the range of Cat Mining Trucks.

e. Bearing capabilities of both sub grade and sub base materials.

f. Wheel loads and soil type determine thickness.

Road Base

Rolling Resistance (RR)

a. RR is a measure of the force that must be overcome to roll or pull a wheel over the ground

b. It’s affected by ground conditions and loads

---> The deeper a wheel sinks into the ground, means : higher RR

RR = 2 % + 0.6 % per cm tire penetration

In practice, a 5% increase in RR can result in up to a 10% decrease in production and a 35% increase in production costs.

Inflection in Haul Road causes a high inertia and unnecessary gear shift point

Grade Resistance (GR)

a. GR is a measure of the force that must be overcome to move a machine over uphill grades

b. GR is ratio between vertical rise/fall and the horizontal distance in which the rise or fall occurs

c. 1 % grade is equivalent to a 1 m rise or fall for every 100 m

* GR as (+) grade for uphill

* GR as (-) grade for downhill

Total Resistance (Effective Grade)

- 1 % = 20 lb/U.S ton = 10 kg/metric ton

- Total Resistance = RR + GR

Example : With a Grade Resistance (GR) of 20 % and Rolling Resistance (RR) of 50 kg/metric ton, find Total Resistance.

Answer :

RR = 50 kg/ metric ton = 50 : 10 = 5 %

Total Resistance = GR + RR = 20 % + 5 % = 25 %

It means, it needs 250 kg force to overcome 1 metric ton

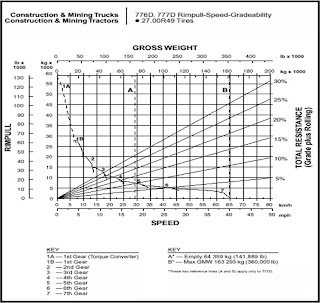

Rimpull-Speed-Gradeability

Rimpull is the force (in kg, lb or KN)

Brake Performance

The speed that can be maintained when the machine is descending a grade with retarder applied

Break Performance Chart

These curves let you determine the safe, controlled downhill speed for a machine based on the “Effective Grade” or grade GR minus RR.

Superelevation

Negotiating curves can generate high lateral tire forces and will contribute to high tire wear. Superelevating the curve helps eliminate these forces. The amount of superelevation depends on the curve’s radius and the speed at which it is negotiated.

Superelevated turns present a danger when slippery. For this reason, curves superelevated over 10% should be used with caution.

Superelevation of Curves

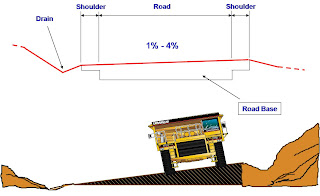

Crossfall

To facilitate effective drainage of a haul road, it is necessary to elevate one side of the haul road from the opposite side.

Recommended Crossfall = 1% - 4%

The limiting criteria for maximum crossfall, is as the slope increases, so does the potential for uneven tyre / bearing wear.

One Way Crossfall

Two Way Crossfall

Drainage

The key to maintaining a haul road in the best structural condition, is to limit the exposure of the surface water and to remove any surface water quickly.

If the construction of complex drainage is not feasible or economic, the simplest way to reduce water damage to a haul road is to elevate the haul road above the lay of the land.

Safety Berm

Berms are an effective way of preventing vehicles from straying into dangerous areas. They can be placed at intersections to control traffic and on the edges of steep slide slopes.

A berm should be a minimum ½ wheel height of the largest wheeled machine on site.

TRAFFIC PATERN

Haul Road Maintenance

a. Grading is the key element to haul road maintenance

b. It facilitates bringing material in from the sides or cutting down high sections and filling the low spots with surplus loose material.

c. After heavy rain, a grader should be used to push the wet surface material to the side of the haul road, to allow it to dry and then be graded back onto the haul road during the next maintenance cycle.

d. The material should be graded to the opposite side from the drain, so that the drain does not fill with the surface material.

e. Always ensure that the initial cross fall is retained.

f. When major repairs are required to a section of road, the following steps need to be carried out:

- Ripping of gravel surface (1st layer)

- Re-shaping of road to original design

- Compaction and watering of surface

SEVERITY ANALYSIS

Severity is dependent on

Severity Rating Table

LOAD PLACEMENT

a. Penempatan material tepat ditengah

b. Minimalkan batuan jatuh (spillage)

Severity Analysis

Truck Payload Measurement System

Lamp Indicator

Payload Operator's Display (POD)

Suspension Cylinder Pressure Sensors on :

1. front left

2. rear right