This part of the publication is concerned with transporting the mineral.

Transporting

Transporting may be categorised as any means of moving the raw product from the working face to the process plant.

The usual method of transporting minerals from the working face is by truck. Large earth moving plant belt conveying systems are the norm for transporting mineral from the primary crusher and from the loaders used in sand and gravel pits. Additionally hydraulic conveying is often used in sand and gravel and clay mining.

This volume will deal with hazards associated with the equipment used.

Transporting the mineral

Heavy vehicles

The main hazards arising from the use large earth moving vehicles are incompetent drivers, brake failure, lack of all around visibility from the drivers position, access to the cab, vehicle movements particularly reversing, roll over, vibration, noise, dust and maintenance. Those most at risk are the driver and pedestrians likely to be struck by the vehicle, and drivers of smaller vehicles, which cannot be seen from the cabs of large vehicles.

Visibility defects can be eliminated by the use of visibility aids such as Closed Circuit Television (CCTV) rear view cameras with monitors situated in the drivers cab, radar and suitable mirrors.

Closed circuit cameras are particularly helpful when reversing towards the edge of a working bench or tipping loads into primary crushers.

Edge protection is always necessary to prevent inadvertent movement over the edge of a roadway, a bench or into a crusher or hopper.

Seat belts will protect drivers in the event of a vehicle roll.

The risk of drivers falling as they gain access to and egress from cabs can largely be eliminated by the provision and maintenance of good access to the cabs and other parts of large vehicles where access is necessary. Any working platform on the vehicle should be suitably protected by outer edge rails.

Good maintenance and regular testing are necessary to reduce the possibility of brake failure.

An area should be set out as a testing area where daily tests are carried out on the effectiveness of a vehicles braking system.

Accidents often occur when vehicles break down. Dumper and similar tipper vehicles should be provided with a scotch or prop to prevent the free fall of components should the hydraulic ram system fail. Access to the vehicles should always be restricted to those people necessary for the work in hand.

Belt conveyors

The hazards associated with belt conveyors are mainly inrunning nips between the belt and driven and direction change rollers and falls from heights.

Those at risk are operators, maintenance staff, persons employed to clean spillage and others using walkways to gain access to other parts of the plant.

Preventative measures include the provision of fixed guarding at all dangerous in running nips, to a distance as to prevent anyone reaching into the nip.

When for any reason it is necessary to remove the guards the belt system should be electrically isolated before any work is carried out.

Unless the conveyor has adequate capacity to carry the maximum load and has been installed at an inclination which eliminates spillage then provision must be made to allow cleaning spillage without removing the guards.

A means of isolating the electrical supply by the provision of switches which lock off the supply activated by pull wires along the length of conveyor runs should be provided.

Falls from a height

Falls from a height often lead to fatal injuries. Many are due to the absence of, or poorly maintained, edge protection.

Adequate and properly maintained walkways and working platforms should be provided along the length of the conveyors. The open side of walkways and platforms should be provided with a suitable hand rail, lower rail and toe boards to prevent persons inadvertently slipping off.

Proper arrangements should be provided for lifting heavy plant during maintenance work.

Hydraulic systems

The hazard is proportional to the pressure of the conveying system.

Those most at risk are the people at either the feed or delivery ends of the system. Should there be the catastrophic break in any other part of the system others may also be at risk. The risk can be largely eliminated by good design, manufacture, installation and maintenance.

Other transport systems

Hazards associated with rail are not too dissimilar from self-propelled vehicular systems and include being struck by or crushed between trucks making up the train.

Those most at risk will be the users of the system although casual pedestrians and vehicle operators may also be at risk.

It is essential that rail systems are properly planned and managed to ensure that there is good control of rail and road traffic. Highly trained operatives and well maintained plant are essential.

Transporting

Transporting may be categorised as any means of moving the raw product from the working face to the process plant.

The usual method of transporting minerals from the working face is by truck. Large earth moving plant belt conveying systems are the norm for transporting mineral from the primary crusher and from the loaders used in sand and gravel pits. Additionally hydraulic conveying is often used in sand and gravel and clay mining.

This volume will deal with hazards associated with the equipment used.

Transporting the mineral

Heavy vehicles

The main hazards arising from the use large earth moving vehicles are incompetent drivers, brake failure, lack of all around visibility from the drivers position, access to the cab, vehicle movements particularly reversing, roll over, vibration, noise, dust and maintenance. Those most at risk are the driver and pedestrians likely to be struck by the vehicle, and drivers of smaller vehicles, which cannot be seen from the cabs of large vehicles.

Visibility defects can be eliminated by the use of visibility aids such as Closed Circuit Television (CCTV) rear view cameras with monitors situated in the drivers cab, radar and suitable mirrors.

Closed circuit cameras are particularly helpful when reversing towards the edge of a working bench or tipping loads into primary crushers.

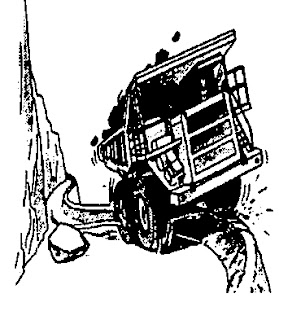

Edge protection is always necessary to prevent inadvertent movement over the edge of a roadway, a bench or into a crusher or hopper.

DIAGRAM 8

Seat belts will protect drivers in the event of a vehicle roll.

The risk of drivers falling as they gain access to and egress from cabs can largely be eliminated by the provision and maintenance of good access to the cabs and other parts of large vehicles where access is necessary. Any working platform on the vehicle should be suitably protected by outer edge rails.

DIAGRAM 9

An area should be set out as a testing area where daily tests are carried out on the effectiveness of a vehicles braking system.

Accidents often occur when vehicles break down. Dumper and similar tipper vehicles should be provided with a scotch or prop to prevent the free fall of components should the hydraulic ram system fail. Access to the vehicles should always be restricted to those people necessary for the work in hand.

Belt conveyors

The hazards associated with belt conveyors are mainly inrunning nips between the belt and driven and direction change rollers and falls from heights.

DIAGRAM 10

Those at risk are operators, maintenance staff, persons employed to clean spillage and others using walkways to gain access to other parts of the plant.

Preventative measures include the provision of fixed guarding at all dangerous in running nips, to a distance as to prevent anyone reaching into the nip.

DIAGRAM 11

DIAGRAM 12

When for any reason it is necessary to remove the guards the belt system should be electrically isolated before any work is carried out.

Unless the conveyor has adequate capacity to carry the maximum load and has been installed at an inclination which eliminates spillage then provision must be made to allow cleaning spillage without removing the guards.

DIAGRAM 13

A means of isolating the electrical supply by the provision of switches which lock off the supply activated by pull wires along the length of conveyor runs should be provided.

DIAGRAM 14

Falls from a height

Falls from a height often lead to fatal injuries. Many are due to the absence of, or poorly maintained, edge protection.

Adequate and properly maintained walkways and working platforms should be provided along the length of the conveyors. The open side of walkways and platforms should be provided with a suitable hand rail, lower rail and toe boards to prevent persons inadvertently slipping off.

DIAGRAM 15

Proper arrangements should be provided for lifting heavy plant during maintenance work.

DIAGRAM 16

Hydraulic systems

The hazard is proportional to the pressure of the conveying system.

Those most at risk are the people at either the feed or delivery ends of the system. Should there be the catastrophic break in any other part of the system others may also be at risk. The risk can be largely eliminated by good design, manufacture, installation and maintenance.

Other transport systems

Hazards associated with rail are not too dissimilar from self-propelled vehicular systems and include being struck by or crushed between trucks making up the train.

Those most at risk will be the users of the system although casual pedestrians and vehicle operators may also be at risk.

It is essential that rail systems are properly planned and managed to ensure that there is good control of rail and road traffic. Highly trained operatives and well maintained plant are essential.