1.1 Introduction

We tend to think of rock mechanics as a modern engineering discipline and yet, as early as 1773, Coulomb included results of tests on rocks from Bordeaux in a paper read before the French Academy in Paris (Coulomb (1776), Heyman (1972)). French engineers started construction of the Panama Canal in 1884 and this task was taken over by the US Army Corps of Engineers in 1908. In the half century between 1910 and 1964, 60 slides were recorded in cuts along the canal and, although these slides were not analysed in rock mechanics terms, recent work by the US Corps of Engineers (Lutton et al (1979)) shows that these slides were predominantly controlled by structural discontinuities and that modern rock mechanics concepts are fully applicable to the analysis of these failures. In discussing the Panama Canal slides in his Presidential Address to the first international conference on Soil Mechanics and Foundation Engineering in 1936, Karl Terzaghi (Terzaghi (1936), Terzaghi and Voight (1979)) said ‘The catastrophic descent of the slopes of the deepest cut of the Panama Canal issued a warning that we were overstepping the limits of our ability to predict the consequences of our actions ....’.

In 1920 Josef Stini started teaching ‘Technical Geology’ at the Vienna Technical University and before he died in 1958 he had published 333 papers and books (Müller (1979)). He founded the journal Geologie und Bauwesen, the forerunner of today's journal Rock Mechanics, and was probably the first to emphasise the importance of structural discontinuities on the engineering behaviour of rock masses.

Other notable scientists and engineers from a variety of disciplines did some interesting work on rock behaviour during the early part of this century. von Karman (1911), King (1912), Griggs (1936), Ide (1936), and Terzaghi (1945) all worked on the failure of rock materials. In 1921 Griffith proposed his theory of brittle material failure and, in 1931 Bucky started using a centrifuge to study the failure of mine models under simulated gravity loading.

None of these persons would have classified themselves as rock mechanics engineers - the title had not been invented at that time - but all of them made significant contributions to the fundamental basis of the subject as we know it today. I have made no attempt to provide an exhaustive list of papers related to rock mechanics which were published before 1960 but the references given above will show that important developments in the subject were taking place well before that date.

Figure 1.1a: The Vajont dam during impounding of the reservoir. In the middle distance, in the centre of the picture, is Mount Toc with the unstable slope visible as a white scar on the mountain side above the waterline.

Figure 1.1b: During the filling of the Vajont reservoir the toe of the slope on Mount Toc was submerged and this precipitated a slide. The mound of debris from the slide is visible in the central part of the photograph. The very rapid descent of the slide material displaced the water in the reservoir causing a 100 m high wave to overtop the dam wall. The dam itself, visible in the foreground, was largely undamaged.

Figure 1.1c: The town of Longarone, located downstream of the Vajont dam, before the Mount Toc failure in October 1963.

Figure 1.1d: The remains of the town of Longarone after the flood caused by the overtopping of the Vajont dam as a result of the Mount Toc failure. More than 2000 persons were killed in this flood.

The early 1960s were very important in the general development of rock mechanics world-wide because a number of catastrophic failures occurred which clearly demonstrated that, in rock as well as in soil, ‘we were over-stepping the limits of our ability to predict the consequences of our actions’ (Terzaghi and Voight (1979)).

In December 1959 the foundation of the Malpasset concrete arch dam in France failed and the resulting flood killed about 450 people. In October 1963 about 2500 people in the Italian town of Longarone were killed as a result of a landslide generated wave which overtopped the Vajont dam. These two disasters had a major impact on rock mechanics in civil engineering and a large number of papers were written on the possible causes of the failures (Jaeger (1972)).

In 1960 a coal mine at Coalbrook in South Africa collapsed with the loss of 432 lives. This event was responsible for the initiation of an intensive research programme which resulted in major advances in the methods used for designing coal pillars (Salamon and Munro (1967)).

The formal development of rock mechanics as an engineering discipline in its own right dates from this period in the early 1960s and I will attempt to review these developments in the following chapters of these notes. I consider myself extremely fortunate to have been intimately involved in the subject since 1958. I have also been fortunate to have been in positions which required extensive travel and which have brought me into personal contact with most of the persons with whom the development of modern rock mechanics is associated.

1.2 Rockbursts and elastic theory

Rockbursts are explosive failures of rock which occur when very high stress concentrations are induced around underground openings. The problem is particularly acute in deep level mining in hard brittle rock. Figure 1.2 shows the damage resulting from a rockburst in an underground mine. The deep level gold mines in the Witwatersrand area in South Africa, the Kolar gold mines in India, the nickel mines centred on Sudbury in Canada, the mines in the Coeur d'Alene area in Idaho in the USA and the gold mines in the Kalgoorlie area in Australia, are amongst the mines which have suffered from rockburst problems.

As early as 1935 the deep level nickel mines near Sudbury were experiencing rockburst problems and a report on these problems was prepared by Morrison in 1942 . Morrison also worked on rockburst problems in the Kolar gold fields in India and describes some of these problems in his book, A Philosophy of Ground Control (1976).

Early work on rockbursts in South African gold mines was reported by Gane et al (1946) and a summary of rockburst research up to 1966 was presented by Cook et al (1966). Work on the seismic location of rockbursts by Cook (1963) resulted in a significant improvement of our understanding of the mechanics of rockbursting and laid the foundations for the microseismic monitoring systems which are now common in

mines with rockburst problems.

A characteristic of almost all rockbursts is that they occur in highly stressed, brittle rock. Consequently, the analysis of stresses induced around underground mining excavations, a key in the generation of rockbursts, can be dealt with by means of the theory of elasticity. Much of the early work in rock mechanics applied to mining was focused on the problem of rockbursts and this work is dominated by theoretical solutions which assume isotropic elastic rock and which make no provision for the role of structural discontinuities. In the first edition of Jaeger and Cook's book Fundamentals of Rock Mechanics (1969), mention of structural discontinuities occurs on about a dozen of the 500 pages of the book. This comment does not imply criticism of this outstanding book but it illustrates the dominance of elastic theory in the approach to rock mechanics associated with deep-level mining problems. Books by Coates (1966) and by Obert and Duvall (1967) reflect the same emphasis on elastic theory.

This emphasis on the use of elastic theory for the study of rock mechanics problems was particularly strong in the English speaking world and it had both advantages and disadvantages. The disadvantage was that it ignored the critical role of structural features. The advantage was that the tremendous concentration of effort on this approach resulted in advances which may not have occurred if the approach had been more general.

Many mines and large civil engineering projects have benefited from this early work in the application of elastic theory and most of the modern underground excavation design methods have their origins in this work.

Figure 1.2: The results of a rockburst in an underground mine in brittle rock subjected

to very high stresses.

Figure 1.3: A wedge failure controlled by intersecting structural features in the rock mass forming the bench of an open pit mine.

1.3 Discontinuous rock masses

Stini was one of the pioneers of rock mechanics in Europe and he emphasised the importance of structural discontinuities in controlling the behaviour of rock masses (Müller (1979)). Stini was involved in a wide range of near-surface civil engineering works and it is not surprising that his emphasis was on the role of discontinuities since this was obviously the dominant problem in all his work. Similarly, the text book by Talobre (1957), reflecting the French approach to rock mechanics, recognised the role of structure to a much greater extent than did the texts of Jaeger and Cook, Coates and Obert and Duvall.

A major impetus was given to this work by the Malpasset dam failure and the Vajont disaster mentioned earlier. The outstanding work by Londe and his co-workers in France (Londe (1965)), Londe et al (1969,1970)) and by Wittke (1965) and John (1968) in Germany laid the foundation for the three-dimensional structural analyses which we have available today. Figure 1.3 shows a wedge failure controlled by two intersecting structural features in the bench of an open pit mine.

1.4 Engineering rock mechanics

Civil and mining engineers have been building structures on or in rock for centuries and the principles of engineering in rock have been understood for a long time. Rock mechanics is merely a formal expression of some of these principles and it is only during the past few decades that the theory and practice in this subject have come together in the discipline which we know today as rock mechanics. A particularly important event in the development of the subject was the merging of elastic theory, which dominated the English language literature on the subject, with the discontinuum approach of the Europeans. The gradual recognition that rock could act both as an elastic material and a discontinuous mass resulted in a much more mature approach to the subject than had previously been the case. At the same time, the subject borrowed techniques for dealing

with soft rocks and clays from soil mechanics and recognised the importance of viscoelastic and rheological behaviour in materials such as salt and potash.

I should point out that significant work on rock mechanics was being carried out in countries such as Russia, Japan and China during the 25 years covered by this review but,due to language differences, this work was almost unknown in the English language and European rock mechanics centres and almost none of it was incorporated into the literature produced by these centres.

1.5 Geological data collection

The corner-stone of any practical rock mechanics analysis is the geological data base upon which the definition of rock types, structural discontinuities and material properties is based. Even the most sophisticated analysis can become a meaningless exercise if the geological information upon which it is based is inadequate or inaccurate.

Methods for the collection of geological data have not changed a great deal over the past 25 years and there is still no acceptable substitute for the field mapping and core logging. There have been some advances in the equipment used for such logging and a typical example is the electronic compass illustrated in Figure 1.4. The emergence of geological engineering or engineering geology as recognised university degree courses has been an important step in the development of rock mechanics. These courses train geologists to be specialists in the recognition and interpretation of geological information which is significant in engineering design. These geological engineers, following in the tradition started by Stini in the 1920s, play an increasingly important role in modern rock engineering.

Once the geological data have been collected, computer processing of this data can be of great assistance in plotting the information and in the interpretation of statistically significant trends. Figure 1.5 illustrates a plot of contoured pole concentrations and corresponding great circles produced by the program DIPS1 developed at the University of Toronto.

Surface and down-hole geophysical tools and devices such as borehole cameras have been available for several years and their reliability and usefulness has gradually improved as electronic components and manufacturing techniques have been improved.

However, current capital and operating costs of these tools are high and these factors, together with uncertainties associated with the interpretation of the information obtained from them, have tended to restrict their use in rock engineering. It is probable that the use of these tools will become more widespread in years to come as further developments occur.

1.6 Laboratory testing of rock

There has always been a tendency to equate rock mechanics with laboratory testing of rock specimens and hence laboratory testing has played a disproportionately large role in the subject. This does not imply that laboratory testing is not important but I would suggest that only about 10 to 20 percent of a well balanced rock mechanics program should be allocated to laboratory testing.

Laboratory testing techniques have been borrowed from civil and mechanical engineering and have remained largely unaltered for the past 25 years. An exception has been the development of servo-controlled stiff testing machines which permit the determination of the complete stress-strain curve for rocks. This information is important in the design of underground excavations since the properties of the failed rock surrounding the excavations have a significant influence upon the stability of the excavations.

1.7 Rock mass classification

A major deficiency of laboratory testing of rock specimens is that the specimens are limited in size and therefore represent a very small and highly selective sample of the rock mass from which they were removed. In a typical engineering project, the samples tested in the laboratory represent only a very small fraction of one percent of the volume of the rock mass. In addition, since only those specimens which survive the collection

and preparation process are tested, the results of these tests represent a highly biased sample. How then can these results be used to estimate the properties of the in situ rock mass ? In an attempt to provide guidance on the properties of rock masses upon which the selection of tunnel support systems can be based, a number of rock mass classification systems have been developed.

Gekom - Small Stratum Compass

Cocla – Geological Stratum compass

Tectronic 4000 – Geological data collector

Figure 1.4: Geological compasses manufactured by F.W. Breihapt & Sohn, P.O. Box 10 05 69,

D-3500 Kassel. W. Germany.

Figure 1.5: Plot of structural features using the program DIPS

Typical of these classifications are those published by Bieniawski (1973, 1974) and by Barton, Lien and Lunde (1974). These classifications include information on the strength of the intact rock material, the spacing, number and surface properties of the structural discontinuities as well as allowances for the influence of subsurface groundwater, in situ stresses and the orientation and inclination of dominant discontinuities. Figure 1.6 reproduces a chart, published by Barton (1989), which can be used for selecting different types of support for underground excavations on the basis of the rock mass classification published by Barton, Lien and Lunde (1974).

These rock mass classification systems have proved to be very useful practical engineering tools, not only because they provide a starting point for the design of tunnel support but also because they force users to examine the properties of the rock mass in a very systematic manner. The engineering judgements which can be made as a result of the familiarity and understanding gained from this systematic study are probably as useful as any of the calculations associated with the classification systems.

Figure 1.6: Chart for preliminary selection of support for underground excavations on the basis of the Tunnelling Quality Index Q published by Barton, Lien and Lunde (1974). The Excavation Support Ratio ESR depends upon the application for which the underground excavation has been designed. After Barton (1989).

1.8 Rock mass strength

One of the major problems confronting designers of engineering structures in rock is that of estimating the strength of the rock mass. This rock mass is usually made up of an interlocking matrix of discrete blocks. These blocks may have been weathered to varying degrees and the contact surfaces between the blocks may vary from clean and fresh to clay covered and slickensided.

Determination of the strength of an in situ rock mass by laboratory type testing is generally not practical. Hence this strength must be estimated from geological observations and from test results on individual rock pieces or rock surfaces which have been removed from the rock mass. This question has been discussed extensively by Hoek and Brown (1980) who used the results of theoretical (Hoek (1968)) and model studies

(Brown (1970), Ladanyi and Archambault (1970)) and the limited amount of available strength data, to develop an empirical failure criterion for jointed rock masses. Hoek (1983) also proposed that the rock mass classification systems, described in the previous section of this paper, can be used for estimating the rock mass constants required for this empirical failure criterion. Practical application of this failure criterion in a number of engineering projects has shown that these estimates are reasonably good for disturbed rock masses but that, in tightly interlocked undisturbed rock masses such as those which may be encountered in tunnelling, the estimated strength values are too low. Further work is required to improve the Hoek-Brown and other failure criteria for jointed rock masses and some ideas on this topic are discussed in a later chapter in these notes.

1.9 In situ stress measurements

The stability of deep underground excavations depends upon the strength of the rock mass surrounding the excavations and upon the stresses induced in this rock. These induced stresses are a function of the shape of the excavations and the in situ stresses which existed before the creation of the excavations. The magnitudes of pre-existing in situ stresses have been found to vary widely, depending upon the geological history of

the rock mass in which they are measured (Hoek and Brown (1980)). Theoretical predictions of these stresses are considered to be unreliable and, hence, measurement of the actual in situ stresses is necessary for major underground excavation design. A phenomenon which is frequently observed in massive rock subjected to high in situ stresses is ‘core disking’, illustrated in Figure 1.7.

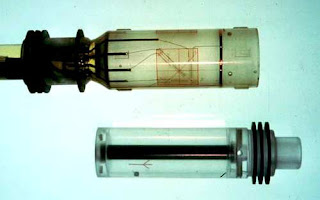

During early site investigations, when no underground access is available, the only practical method for measuring in situ stresses is hydrofracturing (Haimson (1978)) in which the hydraulic pressure required to open existing cracks is used to estimate in situ stress levels. Once underground access is available, overcoring techniques for in situ stress measurement (Leeman and Hayes (1966), Worotnicki and Walton (1976)) can be

used and, provided that sufficient care is taken in executing the measurements, the results are usually adequate for design purposes. One of the instruments used for in situ stress measurement is illustrated in Figure 1.8.

Figure 1.8: A cell for measuring the in situ triaxial stress field in a rock mass, developed in Australia (Worotnicki and Walton 1976).

1.10 Groundwater problems

The presence of large volumes of groundwater is an operational problem in tunnelling but water pressures are generally not too serious a problem in underground excavation engineering (Hoek (1982)). Exceptions are pressure tunnels associated with hydroelectric projects. In these cases, inadequate confining stresses due to insufficient depth of burial of the tunnel can cause serious problems in the tunnel and in the adjacent slopes.

The steel linings for these tunnels can cost several thousand dollars per metre and are frequently a critical factor in the design of a hydroelectric project. The installation of a steel tunnel lining is illustrated in Figure 1.9.

Groundwater pressures are a major factor in all slope stability problems and an understanding of the role of subsurface groundwater is an essential requirement for any meaningful slope design (Hoek and Bray (1981), Brown (1982)).

Figure 1.9: Installation of steel lining in a pressure tunnel in a hydroelectric project.

While the actual distributions of water pressures in rock slopes are probably much more complex than the simple distributions normally assumed in slope stability analyses (Freeze and Cherry (1979)), sensitivity studies based upon these simple assumptions are generally adequate for the design of drainage systems (Masur and Kaufman (1962)).

Monitoring of groundwater pressures by means of piezometers (Brown (1982)) is the most reliable means of establishing the input parameters for these groundwater models and for checking upon the effectiveness of drainage measures In the case of dams, forces generated by the water acting on the upstream face of the dam and water pressures generated in the foundations are critical in the assessment of the stability of the dam. Estimates of the water pressure distribution in the foundations and of the influence of grout and drainage curtains upon this distribution have to be made with care since they have a significant impact upon the overall dam and foundation design (Soos (1979)).

The major advances which have been made in the groundwater field during the past decade have been in the understanding of the transport of pollutants by groundwater. Because of the urgency associated with nuclear and toxic waste disposal in industrialised countries, there has been a concentration of research effort in this field and advances have been impressive. The results of this research do not have a direct impact on conventional geotechnical engineering but there have been many indirect benefits from the development of instrumentation and computer software which can be applied to both waste disposal and geotechnical problems.

1.11 Rock reinforcement

Safety during construction and long term stability are factors which have to be considered by the designers of excavations in rock. It is not unusual for these requirements to lead to a need for the installation of some form of rock support. Fortunately, practical developments in this field have been significant during the past 25 years and today's rock engineer has a wide choice of support systems (Hoek and Brown (1980), Hoek (1982), Farmer and Shelton (1980)).

In tunnelling, there is still an important role for steel sets and concrete lining in dealing with very poor ground but, in slightly better ground, the use of combinations of rockbolts and shotcrete has become very common. The use of long untensioned grouted cables in underground mining (Clifford (1974), Fuller (1983), Hunt and Askew (1977), Brady and Brown (1985)) has been a particularly important innovation which has resulted in significant improvements in safety and mining costs in massive ore bodies. The lessons learned from these mining systems have been applied with considerable success in civil engineering and the use of untensioned dowels, installed as close as possible to the advancing face, has many advantages in high speed tunnel construction. The use of untensioned grouted cables or reinforcing bars has also proved to be a very effective and economical technique in rock slope stabilisation. This reinforcement is installed progressively as the slope is benched downward and it is very effective in knitting the rock mass together and preventing the initiation of ravelling.

The design of rock support systems tends to be based upon empirical rules generated from experience (Lang (1961), Endersbee and Hofto (1963), Cording, Hendron and Deere (1971)) and currently available analytical models are not very reliable. Some interesting theoretical models, which provide a very clear understanding of the mechanics of rock support in tunnels, have been developed in recent years (Rabcewicz (1969), Daeman (1977), Brown et al (1983), Brown and Bray (1982)). These models have to be used with caution when designing actual tunnel support since they are based upon very simple assumptions and rock conditions underground may vary from these assumptions.

With the development of powerful numerical models such as that described by Lorig and Brady (1984), more realistic and reliable support designs will eventually become possible but it will be several years before these models can be used as design tools.

1.12 Excavation methods in rock

As pointed out earlier, the strength of jointed rock masses is very dependent upon the interlocking between individual rock pieces. This interlocking is easily destroyed and careless blasting during excavation is one of the most common causes of underground excavation instability. The following quotation is taken from a paper by Holmberg and Persson (1980) :

The innocent rock mass is often blamed for insufficient stability that is actually the result of rough and careless blasting. Where no precautions have been taken to avoid blasting damage, no knowledge of the real stability of the undisturbed rock can be gained from looking at the remaining rock wall. What one sees are the sad remains of what could have been a perfectly safe and stable rock face.

Techniques for controlling blast damage in rock are well-known (Svanholm et al (1977), Langefors and Kihlstrom (1963), Hagan (1980)) but it is sometimes difficult to persuade owners and contractors that the application of these techniques is worthwhile.

Experience in projects in which carefully controlled blasting has been used generally shows that the amount of support can be reduced significantly and that the overall cost of excavation and support is lower than in the case of poorly blasted excavations (Hoek (1982)). Examples of poor and good quality blasting in tunnels are illustrated in Figures 1.10 and 1.11.

Machine excavation is a technique which causes very little disturbance to the rock surrounding an underground excavation. A wide range of tunnelling machines have been developed over the past 25 years and these machines are now capable of working in almost all rock types (Robbins (1976), McFeat-Smith (1982)). Further development of these machines can be expected and it is probable that machine excavation will play a much more important role in future tunnelling than it does today.

1.13 Analytical tools

Analytical models have always played an important role in rock mechanics. The earliest models date back to closed form solutions such as that for calculating the stresses surrounding a circular hole in a stressed plate published by Kirsch in 1898. The development of the computer in the early 1960s made possible the use of iterative numerical techniques such as finite element (Clough (1960)), boundary element (Crouch and Starfield (1983)), discrete element (Cundall (1971)) and combinations of these methods (von Kimmelmann et al (1984), Lorig and Brady (1984)). These have become almost universal tools in rock mechanics.

Figure 1.10: An example of poor blasting in a tunnel.

Figure 1.11: An example of good blasting in a tunnel.

The computer has also made it much more convenient to use powerful limit equilibrium methods (Sarma (1979), Brown and Ferguson (1979), Shi and Goodman (1981), Warburton (1981)) and probabilistic approaches (McMahon (1971), Morriss and Stoter (1983), Priest and Brown (1982), Read and Lye (1983)) for rock mechanics studies.

The recent advent of the micro-computer and the rapid developments which have taken place in inexpensive hardware have brought us close to the era of a computer on every professional's desk. The power of these machines is transforming our approach to rock mechanics analysis since it is now possible to perform a large number of sensitivity or probabilistic studies in a fraction of the time which was required for a single analysis a

few years ago. Given the inherently inhomogeneous nature of rock masses, such sensitivity studies enable us to explore the influence of variations in the value of each input parameter and to base our engineering judgements upon the rate of change in the calculated value rather than on a single answer.

1.14 Conclusions

Over the past 25 years, rock mechanics has developed into a mature subject which is built on a solid foundation of geology and engineering mechanics. Individuals drawn from many different disciplines have contributed to this subject and have developed a wide range of practical tools and techniques. There is still a great deal of room for development, innovation and improvement in almost every aspect of the subject and it is a field which will continue to provide exciting challenges for many years to come.