GENERAL STRUCTURE

S6D140-1

1. Fan pulley

2. Cylinder block

3. Cylinder liner

4. Exhaust valve

5. Piston

6. Rocker arm housing

7. Rocker arm housing cover

8. Intake valve

9. Camshaft

10. Cam follower

11. Crankshaft pulley

12. Vibration damper

13. Front cover

14. Under frame

15. Crankshaft gear

17. Connecting rod

18. Oil strainer

19. Oil pan

20. Crankshaft

21. Main bearing cap

22. Flywheel

23. Flywheel housing

25. Exhaust manifold Engine : S6D140-1 (with turbocharger)

26. Cylinder head SA6D140-1 (with turbocharger and after -cooler )

27. Oil cooler

28. Oil pump

29. Intake connector pipe

Type : In-line, 6-cylinder, water-cooled, direct fuel injection, 4-cycle diesel engine

30. Electrical intake air heater

31. Intake manifold

32. Push rod

33. Dipstick

VALVE SYSTEM

Engine No. 10001 - 19603

1. Thrust plate

2. Camshaft gear

3. Camshaft

4. Cam roller

5. Cam roller pin

6. Cam follower shaft

7. Cam follower

8. Push rod

9. Rocker arm shaft

10. Rocker arm

11. Lock nut

12. Rocker arm adjustment screw

13. Cross head adjustment screw

14. Lock nut

15. Cross head

16. Upper spring seat

17. Outer valve spring

18. Inner valve spring

19. Exhaust valve

20. Valve guide

21. Lower spring seat

22. Intake valve

CAM SHAFT

• Stamp forging

• Journal and cam portion:

Induction hardening

MAIN CIRCULATION SYSTEM

1. Piston

2. Piston pin

3. Connecting rod, bushing .

4. Top ring

5. Second ring

6. Oil ring

7. Crankshaft pulley

8. Vibration damper

9. Crankshaft

10. Crankshaft gear

11. Connecting rod bearing

12. Connecting rod cap

13. Connecting rod

14. Connecting rod cap mounting bolt

CRANKSHAFT

• Stamp forging

• Journal and filet portion:

Induction hardening

PISTON

• Ductile cast iron

CONNECTING ROD

• Stamp forging

TIMING GEAR

1. Water pump drive gear (No. of teeth : 23)

2. Sub idler gear (No. of teeth : 42)

3. Main idler gear (Large) (No. of teeth : 60)

4. Main idler gear (Small) (No. of teeth : 40)

5. Camshaft gear (No. of teeth : 48)

6. PTO gear (OPTION) (No. of teeth : 14)

7. Compressor drive gear (No. of teeth : 24)

8. Fuel injection pump drive gear (No. of teeth : 46)

9. PTO gear (OPTION) (No. of teeth : 22)

10. Crankshaft gear (No. of teeth : 36)

11. Oil pump drive gear (No. of teeth : 22)

A, B, C: Match marks

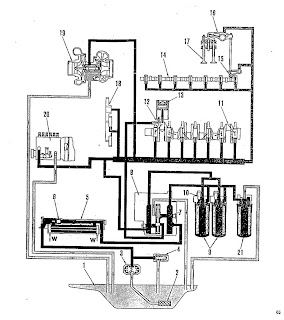

LUBRICATION SYSTEM CHART

1. Oil pan

2. Oil strainer

3. Oil pump

4. Main relief valve

5. Oil cooler

6. Thermostat

7. Regulator valve

8. Valve adapter

9. Oil filter

10. Safety valve

11. Crankshaft

12. Piston cooling nozzle

13. Piston

14. Camshaft

15. Cam follower

16. Rocker arm

17. Intake and exhaust valve

18. Timing gears

19. Turbocharger

20. Fuel injection pump

W : Cooling water

LARGE CAPACITY OIL FILTER + BY PASS FILTER

1. Oil pan

2. Oil strainer

3. Oil pump

4. Main relief valve

5. Oil cooler

6. Thermostat

7. Regulator valve

8. Valve adapter

9. Oil filter ( full flow filter x 2 )

10. Safety valve

11. Crankshaft

12. Piston cooling nozzle

13. Piston

14. Camshaft

15. Cam follower

16. Rocker arm

17. Intake and exhaust valve

18. Timing gears

19. Turbocharger

20. Fuel injection pump

21. Bypass filter

W : Cooling water

FUEL SYSTEM CHART

1. Fuel tank

2. Gauze filter

3. Priming pump

4. Feed pump

5. Fuel filter

6. Fuel injection pump

7. Fuel injection nozzle

8. Over-flow valve

FUEL INJECTION PUMP

1. Fuel injection pipe (No. 1 )

2. Fuel injection pipe (No. 2) -

3. Fuel injection pipe (No. 3)

4. Fuel injection pipe (No. 4)

5. Fuel injection pipe (No. 5)

6. Fuel injection pipe (No. 6)

7. Air bleeder plug

8. Oil tube (inlet)

9. Fuel injection pump drive gear (No. of teeth 48)

10. Fuel injection pump drive shaft

11. Bearing box

12. Coupling

13. Feed pump

14. Fuel injection pump

15. Gauze filter

16. Oil tube (outlet)

17. Fuel filter

FUEL INJECTION NOZZLE

1. Fuel inlet connector

2. Nozzle holder

3. Adjustment shim.

4. Spring

5. Seat

6. Spacer

7. Nozzle

8. Retaining cap

9. Needle valve

FUEL INJECTION NOZZLE

• Maker : DIESEL KIKI ( S6D140-1 )

NIPPO DENSO ( SA6D140-1 )

• Type : Multi-hole nozzle

• Injection pressure : 250 kg/cm ²

• Adjusting injection pressure : Shim adjusting type.

b. Injection (To cylinder)

c. Fuel return (To fuel tank)

S6D140-1: Made by DIESEL KIKI

(Diameter of nozzle hole 0.35 x 7 hole)

SA6D140-1: Made by DIESEL KIKI

Made by NIPPON DENSO

(Diameter of nozzle hole 0.36 x 6 hole)

COOLING SYSTEM CHART

1. Radiator

2. Thermostat

3. After-cooler (SA6D140-1)

4. Air compressor (if equipped)

5. Water pump

A. Lubrication

6. Oil cooler

7. Corrosion resistor

8. Cooling fan

MEASURING BLOW - BY PRESSURE

Measure the blow by pressure under the following conditions.

Temperature of cooling water:

Within operating range

Temperature of hydraulic oil: 45 - 55°C

1. Set tool E4 and E, to blow by hose (1).

2. Use tool E3 to connect tool E, and E2.

3. Run the engine at the rated output and measure the blow by pressure as follows.

- Blow by varies greatly according to the condition of the engine. Therefore, if the blow by value is considered abnormal, check for problems connected with defective blow by, such as excessive oil consumption, defective exhaust gas color, and prematurely dirty or deteriorated oil.

- When taking measurements, be careful not to touch any hot parts or rotating parts.

1) Before starting measurements,. set the work equipment to the following posture.

A: When setting the work equipment in position, be careful not to let the blade hit the tire.

B: For the draw bar shift, take the center position as the standard position.

C: Shift the blade fully to the right.

D: Rotate the circle to give a propulsion angle of 50°.

E: Raise the blade fully on both the left and right sides.

2) Pull right blade lift lever (1) back, and hold it at the end of its stroke.

- Raise the right end of the blade, and relieve the circuit.

3) In the condition in Step 2), operate blade left shift lever (2) and circle left rotation lever (3) at the same time to the front to move the work equipment.

- Use the blade left shift lever and the circle left rotation lever to set the oil discharge amount to the maximum .

MEASURING COMPRESSION PRESSURE

When measuring the compression pressure, be careful not to touch the exhaust manifold or muffler, or to get caught in rotation parts.

1. Adjust valve clearance.

- For details, see TESTING AND ADJUSTING VALVE CLEARANCE.

2. Warm up engine (oil temperature 40 - 60°C).

3. Remove nozzle holder assembly.

4. Install tool Dz to the nozzle holder mount, then connect pressure gauge D,.

5. Set engine tachometer in position.

6. Disconnect connector (2) of stop motor (1), set to the NO INJECTION position, then crank the engine and measure the compression pressure.

- Measure the compression pressure at the point where the pressure gauge indicator remains steady.

- When measuring the compression pressure, measure the engine speed to confirm that it is within the specified range

TESTING AND ADJUSTING VALVE CLEARANCE

- Adjust clearance between rocker lever and top of cross head to following value.

Intake valve (at 20°C) Exhaust valve (at 20°C) 0.43 mm 0.80 mm

1. Remove cylinder head cover (1).

2. Rotate the crankshaft in the normal direction to align pointer (2) with the 1.6 TOP mark of crankshaft pulley. When rotating, check the movement of the intake valve of No. 1 cylinder and No. 6 cylinder. Set with No. 1 cylinder at compression top dead center.

3. When No. 1 cylinder is at compression top dead center, adjust the valves marked

- Then rotate the crankshaft one turn in the normal direction, set No. 6 cylinder to compression top dead center, and adjust the valves marked O.

4. To adjust, insert tool F between rocker lever (3) and cross head (4) and turn adjustment screw (5) until clearance is a sliding fit.

Tighten lock nut (6) to hold adjustment screw in position.

Lock nut: 58.8 t 5.9 Nm (6.0 t 0.6 kgm)

5. Then rotate the crankshaft in the normal direction by one turn and adjust the valve clearance for the remaining valves marked o.

- After adjusting No. 1 cylinder at compression top dead center, it is also possible to turn the crankshaft 120° each time and adjust the valve clearance of each cylinder according to the firing order.

• Firing order: 1 - 5 - 3 - 6 - 2 - 4

- After tightening the lock nut, check the clearance again.