SELF THRUSTING QUIET ROCKDRILL

NOISE LEVELS

IN STOPE TESTING

STANDARD S215

QUIET ROCKDRILL

ROOF SUPPORT FOR TABULAR STOPES

a. Maximum loading: 20 ton/leg

b. Energy absorption: 40kJ/m^2

c. Maximum closure speed: 3 m/s

d. Maximum deflection at closure: 150 mm

e. Slow yield: 30 mm/day

f. Slow yield closure: 150 mm (maximum)

g. Preloading: 10 ton

h. Maximum contact stress: 30 MPa

TESTING IN SAVUKA – 40 kJ at 3m/s

ROOF SUPPORT FOR ROCKFALL MINES

END OF WIND PROTECTION SYSTEM

• AN OVERWIND/UNDERWIND SITUATION TAKES PLACE

WHEN THE CONVEYENCE IS PULLED BEYOND ITS OPERATIONAL LIMIT IN THE HEADGEAR OR SHAFT BOTTOM

--------=

MAXIMUM DECELARATION

- OVERWIND: 1g

- UNDERWIND: 2.5g

--------=

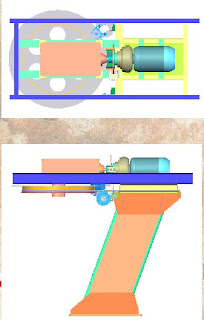

MECHANICAL SYSTEM

END OF WIND PROTECTION SYSTEM

SYSTEM DETAIL

• NEW DETACHING MECHANISM ON TOP OF CAGE

• NO ACCIDENTAL DETACHING POSSIBLE

- CYCLIC BENDING PLATE

- STAINLESS STEEL CABLE

CHAIRLIFTS

- Motor size: 25 to 132 kW

- Wheel size: 1200 and 1500

- Length of installation: 200m @ 34° to 1940 @ 4°

- Typical: 900 people per hour (1.5 m/s)

- Low Maintenance

- Ease of operation

- Modern design

FEM PLOT WITH 2.5 SAFETY FACTOR

Harties no 5 shaft

290 m @ 34°

ROOFBOLTING

• Testing of spin to stall resins

– Building of inexpensive resin tester for QA

– Determining effect of:

• Spin speed/time

• Torque

• Moisture

• Bolt profile

• Temperature

• Development of polyurethane bolting system

• Development of spin to stall washers