Calculation of production

When planning mechanized projects, one extremely important issue is how to calculate the production of the

machines. The first step when estimating the production is to calculate a theoretical value as explained below. This theoretical value is then adjusted according to actual figures obtained from past experience in similar operations.

On the basis of these figures (particularly those for job efficiency) it will be possible to determine values suitable for the project which will be neither over-optimistic nor wasteful. Therefore it is first necessary to fully understand the theoretical calculations and to be able to obtain a figure for working efficiency which is feasible on that job site. From this it is possible to obtain a realistic figure for the work volume that can be attained.

Method of calculating production

It is usual to express the production of construction machines in terms of production per hour (m3/h or cu.yd./h). This is basically calculated from the haul volume per cycle, and the number of cycles.

where :

Q : Hourly production (m3/hr; yd3/hr)

q : Production (m3; yd3) per cycle, of loose, excavated soil

(This is determined by the machine capacity.)

N : Number of cycles per hour = 60/cm

Cm : Cycle time (in minutes)

E : Job efficiency (see the item 2)

1. Earth volume conversion factor (f)

The volume of any amount of earth depends on whether the soil is in its natural ground condition (that is, unexcavated), whether it is loose, or whether it has been compacted. This conversion factor depends on the type of soil and the operating state, but as a general rule, the values in the following table are used.

To obtain only the productivity of a construction machine, the earth volume conversion factor is taken as Table 1 and machine productivity is expressed in terms of loose earth. However, when planning actual projects, work volume is calculated in terms of unexcavated earth or compacted earth, so care must be taken to convert these figures.

Example:

1,000 m3 of unexcavated earth has to be hauled.

a) What will its volume be when it has been excavated ready for hauling?

b) What will its volume be if it is then compacted?

Bulldozers

(DOZING)

The hourly production of a bulldozer when excavating or dozing can be obtained by using the following fomula:

where :

Q : Hourly production (m3 /hr; yd3/hr)

q : Production per cycle (m3; yd3)

Cm: Cycle time (in minutes)

e : Grade factor

E : Job efficiency

1. Production per cycle (q)

For dozing operations, the production per cycle is theoretically calculated as follows:

q = q1 × a

q1 : Blade capacity (m3; yd3)

a : Blade fill factor

When calculating the standard productivity of a bulldozer, the figure used for the volume of earth hauled in each cycle, was taken as blade capacity. In fact, production per cycle differs with the type of soil, so the blade fill factor is used to adjust this figure. See Table 2 to select the factor.

Table 2 Blade Fill Factor (a)

2. Cycle time (Cm)

The time needed for a bulldozer to complete one cycle (dozing, reversing and gear shifting) is calculated by

the following formula:

where

D : Haul distance (m; yd)

F : Forward speed (m/min.; yd./min.)

R : Reverse speed (m/min.; yd./min.)

Z : Time required for gear shifting (min.)

(1) Forward speed/reverse speed

As a rule a speed range of 3-5 km/h for forward, and 5-7 km/h for reverse should be chosen.

(2) Time required for gear shifting

Dozer Shovels Wheel Loaders

(LOADING)

Generally, the hourly production can be obtained by using the following formula:

where

Q : Hourly production (m3 /hr; yd3 /hr)

q : Production per cycle (m3; cu.yd3)

Cm : Cycle time (min.)

E : Job efficiency

1. Production per cycle (q)

q = q1 × K

Where q1: The heaped capacity given in the specifications sheet

K : Bucket fill factor ............The actual volume in the bucket differs depending on the type of loading material.

Bucket fill factor is used for that reason.

(1) Bucket fill factor

Table 3 Bucket fill factor

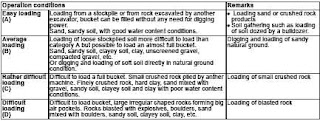

Table 4 Loading conditions

2. Cycle time (Cm)

The following tables show the standard cycle time according to loading method and operating conditions.

It is possible to shorten a cycle time still more than the standard cycle time by minimizing moving distance.

Hydraulic Excavators

(Excavating and loading)

where

Q : Hourly production (m3 /hr; yd3 /hr)

q : Production per cycle (m3; yd3)

Cm : Cycle time (sec.)

E : Job efficiency

1. Production per cycle (q)

q = q1 × K

where

q1: Bucket capacity (heaped) (m3; yd3)

K : Bucket fill factor

(1) Bucket fill factor

The bucket fill factor varies according to the nature of material. A suitable factor can be selected from the table, taking into consideration the applicable excavating conditions.

Table 9 Bucket fill factor (Backhoe)

Table 10 Bucket fill factor (Loading shovel)

Off-Highway Dump Trucks

When carrying out operations using a suitable number of dump trucks of suitable capacity to match the loader, the operating efficiency is calculated in the following order:

1. Estimating the cycle time

The cycle time of a dump truck consists of the following factors.

(1) Time required for loader to fill dump truck

(2) Hauling time

(3) Time required for unloading (dumping) plus time expended for standby until unloading is started.

(4) Time required for returning

(5) Time required for dump truck to be positioned for loading and for the loader to start loading

Accordingly, the cycle time = (1) + (2) + (3) + (4) + (5)

The cycle time is calculated as follows:

Cycle time of dump truck (Cmt)

(1) : Loading time

(2) : Hauling time

(3) : Dumping time

(4) : Returning time

(5) : Spot and delay time

Where,

n: Number of cycles required for loader to fill dump truck

n = C1 / (q1 × K)

C1 : Rated capacity of dump truck (m3, yd3)

q1 : Bucket capacity of loader (m3, yd3)

K : Bucket fill factor of loader

Cms: Cycle time of loader (min)

D: Hauling distance of dump truck (m, yd)

V1: Average speed of loaded truck (m/min, yd/min)

V2: Average speed of empty truck (m/min, yd/min)

t1: Time required for dumping + time required for standby until dumping is started (min)

t2: Time required for truck to be positioned and for loader to start loading (min)

1) Loading time

The time required for a loader to load a dump truck is obtained by the following calculation.

Loading time = Cycle time (Cms) × No. of cycles to fill dump truck (n)

a) Cycle time of loader (Cms)

The cycle time of a loader is dependent on the type of loader (excavator, crawler type loader, wheel loader, etc.). For the cycle time of loaders, refer to the section pertaining to the estimation of the production of loaders.

Motor Graders

The motor grader is used for many purposes such as maintaining roads, final finishing for earthmoving projects, trenching and bank cutting. Therefore there are many methods of expressing its operating capacity.

1. Calculating the hourly operating area (m2/h)

QA = V × (Le - Lo) × 1000 × E

Where :

QA : Hourly operating area (m2/hr)

V : Working speed (km/hr)

Le : Effective blade length (m)

Lo : Width of overlap (m)

E : Job efficiency

NOTE: Graders usually operate on long stretches, so the time required for gear shifting or turning can be ignored.

1) Working speed (V)

Road repair : 2 to 6 km/h Trenching : 1.6 to 4 km/h

Bank finishing: 1.6 to 2.6km/h Snow-removal: 7 to 25 km/h

Field grading : 1.6 to 4 km/h Leveling : 2 to 8 km/h

2) Effective blade length (Le), width of overlap (Lo)

Since the blade is normally angled when cutting or grading the surface, the effective blade length depends on the angle. The width of overlap is usually 0.3 m. Following table gives the values to be used when applying the formula.

3) Job efficiency (E)

The following table gives typical job efficiency as a rough guide. To obtain the actual production figure, determine the efficiency in accordance with actual operating conditions.

2. When calculating the time required to finish a specific area.

Where

T = Working time (h)

N = Number of trips

D = Working distance (km)

V = Working speed (km/hr)

E = Job efficiency

Compactors

Number of trips (N)

When a grader is operating in a job site, and leveling parallel strips, the number of trips can be calculated by using the following formula:

Where

W : Total width to be leveled (m)

Le : Effective blade length (m)

Lo : Width of overlap (m)

n : Number of grading required to finish the surface to the required flatness.

There are two ways of expressing the productivity of compactors: by the volume of soil compacted, and by the area compacted.

1. Expressing productivity by the volume of soil compacted.

When calculating the productivity by the volume of soil compacted, the following formula is used.

Where

Q = Hourly production (m3/hr)(volume of soil compacted)

V = Operating speed (km/hr)

W= Effective compaction width per pass (m)

H = Compacted thickness for one layer (m)

N = Number of compaction (number of passes by compactor)

E = Job efficiency

1) Operating speed (V)

As a general rule the following values are used.

2) Effective compaction width (W)

3) Compacted thickness for one layer

Compacted thickness is determined from compaction specifications or from the results of tests, but as a general rule, it is 0.2 ~ 0.5 m in loosened soil.